Basic Engineering Package: A Complete Guide for Instrumentation Engineers

The Basic Engineering Package is the foundation of any industrial project. It includes all the essential documents, drawings, and specifications needed to start detailed engineering and procurement. Whether you’re a student, fresher, or working engineer, understanding this package is key to mastering instrumentation and control systems.

Table of Contents

Engineering Design Project Organogram in Basic Engineering Package

The Basic Engineering Package includes an organogram that shows the structure of the engineering team. It helps define who is responsible for what and how different roles connect with each other. This avoids confusion and improves teamwork.

It also shows how departments like instrumentation, mechanical, electrical, and civil work together. This structure supports better planning and faster decision-making.

- Shows team roles and responsibilities

- Improves communication between departments

- Supports project planning and execution

- Reduces confusion and delays

Client Specifications and Standards in Basic Engineering Package

Client specifications and standards are a key part of the Basic Engineering Package. These are the rules and requirements given by the client. They guide the design, safety, and performance of the entire project.

Following these standards helps engineers meet client expectations. It also makes the approval process faster and reduces the chances of rework.

- Defines technical and safety requirements

- Ensures compliance with client expectations

- Helps in faster approvals and fewer revisions

- Acts as a reference for all design decisions

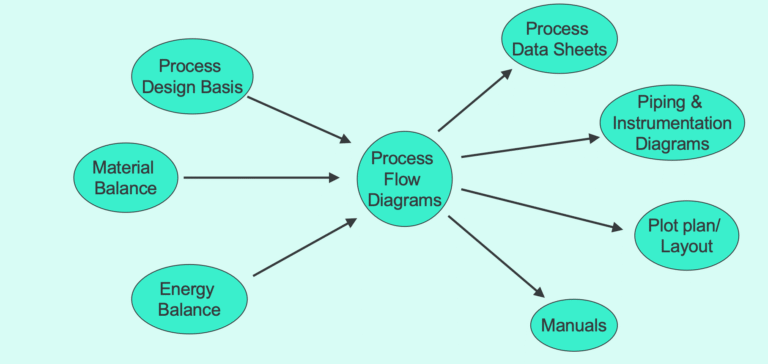

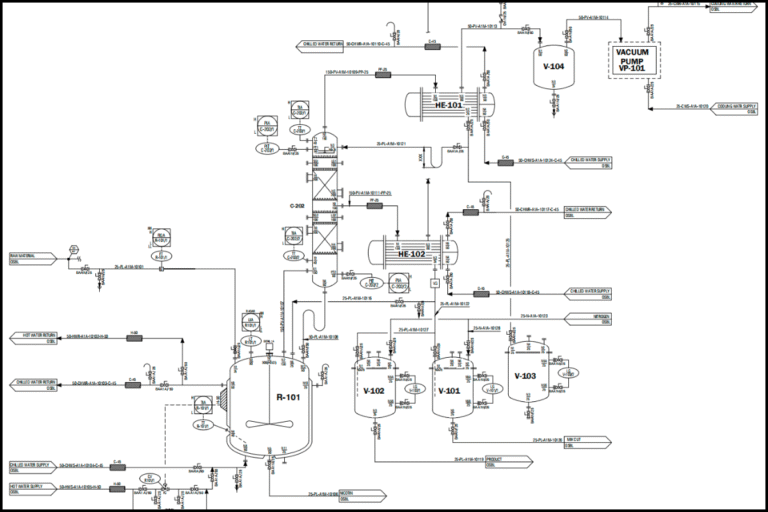

Introduction to PFD, P&ID, and PDS

The Basic Engineering Package includes three important documents: PFD (Process Flow Diagram), P&ID (Piping and Instrumentation Diagram), and PDS (Process Data Sheet). These documents help engineers understand the process and control systems.

PFD shows the overall flow of materials and energy. P&ID gives detailed information about instruments, valves, and control loops. PDS contains technical data for each instrument or equipment

- PFD shows process flow and major equipment

- P&ID includes instruments, valves, and control loops

- PDS provides technical data for selection and procurement

- All three documents are essential for design and review

PMS, Line List, Equipment Data Sheets

The Basic Engineering Package also includes PMS (Piping Material Specification), Line List, and Equipment Data Sheets. These documents provide technical details about pipes, lines, and equipment used in the plant.

PMS defines the type of pipes and fittings. Line List gives details like size, service, and insulation. Equipment Data Sheets describe pumps, compressors, and other machinery.

- PMS defines pipe materials and standards

- Line List includes pipeline details and services

- Equipment Data Sheets describe machinery specs

- Useful for procurement and installation planning

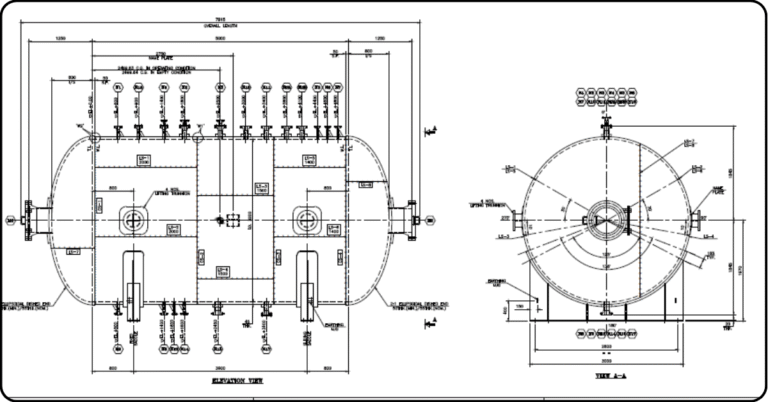

Fabrication Drawings

Fabrication drawings are detailed technical drawings used to manufacture and assemble components. They include dimensions, materials, welding details, and tolerances. These drawings are used by fabricators to build parts accurately.

They also help in quality control and ensure that the final product matches the design. Any mistake in these drawings can lead to costly errors during construction.

- Shows dimensions and material details

- Used for manufacturing and assembly

- Helps in quality control and inspection

- Reduces errors and ensures design accuracy

ISA Codes and Standards

ISA (International Society of Automation) standards are global guidelines for instrumentation and control systems. They cover everything from symbols used in drawings to installation practices and calibration methods.

Using ISA standards ensures consistency across projects. It also helps engineers understand and follow best practices in instrumentation design.

- Provides global guidelines for instrumentation

- Ensures consistency and safety in design

- Helps in calibration and installation practices

- Widely accepted across industries

Design Basis

The design basis is a document that explains the assumptions, criteria, and scope of the engineering design. It includes process conditions, control philosophy, and safety requirements. This document is the starting point for all technical decisions.

It helps engineers stay aligned with project goals and ensures that the design meets operational needs. Without a clear design basis, the project can face delays and mismatches.

- Defines scope and assumptions of design

- Includes control philosophy and safety norms

- Acts as a reference for all engineering decisions

- Helps maintain alignment with project goals

Interdiscipline Coordination

Interdiscipline coordination means working together with other departments like mechanical, electrical, civil, and process. It ensures that all designs are integrated and there are no clashes between systems.

For example, an instrument may need a cable tray from electrical and a support from civil. Coordination avoids delays and ensures smooth execution during construction.

- Promotes teamwork across departments

- Avoids design clashes and installation issues

- Improves project efficiency and timelines

- Essential for integrated engineering solutions

Conclusion: Why Understanding the Basic Engineering Package Matters

The Basic Engineering Package is not just a set of documents—it’s the backbone of every successful engineering project. From organograms and client standards to PFDs, P&IDs, and fabrication drawings, each element plays a vital role in planning, designing, and executing industrial systems. For instrumentation engineers, mastering these components means gaining control over process design, safety, and coordination. Whether you’re working in oil and gas, chemical plants, power generation, or any other engineering sector, this knowledge will help you grow with confidence and clarity.

If you’re serious about building a strong career in instrumentation design, then you should definitely explore the Instrumentation Design Engineering course at Petromech Baroda LLP. We teach everything in detail—from basic engineering packages to advanced control systems—with practical examples and real-world applications. Our course is designed to help freshers and working professionals become job-ready for industries like oil & gas, chemical, power, and more. So if you’re looking for a trusted institute that truly empowers engineers, visit Petromech Baroda LLP or send us an enquiry today. Your future in instrumentation starts here.

Pingback: Field Instrumentation Material Requisition: Types, Selection & Datasheets

Pingback: Control System Engineering: 14 Key Deliverables Every Instrumentation Engineer Should Know