Piping Design Vs Process Design: Which Career Suits You?

Confused between piping and process design? Let’s explore both careers in simple words and clear facts!

Table of Contents

Piping Design vs Process Design Career — this is a common question among engineering students and fresh graduates. Both fields are important in industries like oil & gas, chemical, pharma, and manufacturing. But they are different in terms of skills, software, and job roles.

Let’s understand both careers in simple words.

What is Piping Design?

Piping Design means planning how pipes will carry fluids like water, oil, steam, or gas inside a plant or factory. It is part of mechanical engineering and used in industries like oil & gas, power plants, and chemical factories.

🔹 Key Points:

- Piping engineers create pipe layouts, supports, valves, and fittings.

- They use software like AutoCAD, PDMS, SmartPlant, and E3D.

- Knowledge of materials, pressure, temperature, and safety codes is important.

- They work with civil, mechanical, and instrumentation teams.

- Piping design is more about layout, routing, and mechanical drawings.

👉 If you enjoy drawing layouts and working with technical diagrams, piping design is a great career option.

What is Process Design?

Process Design means planning how raw materials will be converted into final products. It is mostly used in chemical, oil & gas, food, and pharma industries.

🔹 Key Points:

Process engineers design equipment like reactors, heat exchangers, distillation columns, and separators.

They use simulation software such as Aspen HYSYS, ChemCAD, and DWSIM to model and optimize processes.

They perform line sizing and pump hydraulics calculations to ensure smooth fluid flow.

They also calculate the correct size of control valves and pressure safety valves for safe operation.

Process engineers conduct HAZOP studies to identify risks and improve plant safety.

They contribute to layout engineering, helping design efficient and safe plant structures.

A strong understanding of chemistry, thermodynamics, and process flow is essential.

This field is ideal for chemical, mechanical, and instrumentation engineers.

👉 If you enjoy solving chemical problems and working with flow diagrams, process design is for you.

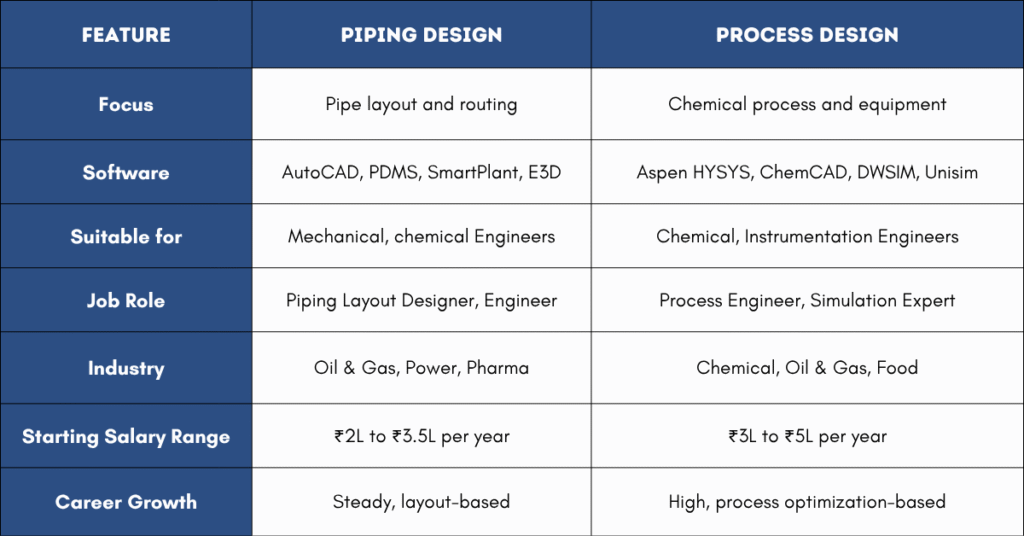

Piping Design vs Process Design: Key Differences

Piping Design and Process Design are two different parts of engineering work. Piping Design is about planning how pipes are placed and connected in a plant. Process Design is about how chemicals and equipment work together to make a product. Both use different software and need different skills. This table will help you understand which one suits your interest and career goals better.

What are the engineering deliverables of Piping Design and Process Design?

Engineering deliverables are the final documents, drawings, and reports created during a project. They help in construction, installation, and operation of a plant. Piping Design and Process Design have different types of deliverables based on their roles. Below is a simple list for each.

Piping Design Deliverables

- Piping Layout Drawings – Shows how pipes are placed in the plant.

- Isometric Drawings – 3D-like drawings for pipe fabrication and installation.

- Pipe Support Details – Information about how pipes are held and supported.

- Material Take-Off (MTO) – List of materials needed for piping work.

- Piping Specification Sheets – Standards and rules for pipe types and fittings.

- Line List – Summary of all pipe lines with size, service, and specs.

- Stress Analysis Reports – Checks if pipes can handle pressure and temperature.

- Valve and Instrument List – Details of valves and instruments connected to pipes.

- Welding and Testing Procedures – Steps for joining pipes and checking quality.

- Process Flow Diagram (PFD) – Shows the main steps of the chemical process.

- Piping and Instrumentation Diagram (P&ID) – Detailed drawing of equipment, pipes, and instruments.

- Heat and Material Balance – Shows how much heat and material is used and produced.

- Process Datasheets – Technical details of equipment like pumps, vessels, and exchangers.

- Simulation Reports – Results from software showing how the process works.

- Control Philosophy – Explains how the process will be controlled and automated.

- Safety and Relief System Design – Plans for handling pressure and emergency situations.

- Utility Requirement List – Shows what utilities (steam, water, air) are needed.

- Process Description Document – Simple explanation of how the process works.

Final Thoughts: Which Career Should You Choose?

Choosing between piping design vs process design depends on your engineering background, personal interest, and career goals. Both fields offer excellent opportunities in industries like oil & gas, chemical, pharma, and manufacturing.

If you are a mechanical engineer and want to understand which career suits you best, this blog will help you compare piping design vs process design clearly. To explore why piping engineering is often a better option for mechanical engineers, read this detailed guide on its scope, benefits, and industry demand.

On the other hand, if you are from a chemical or instrumentation engineering background and love solving process-related problems, optimizing plant performance, and working with simulation tools, then process design is the right path. It involves designing chemical processes, sizing equipment, and ensuring safety and efficiency.

Both careers require different skill sets, but they share a common goal — building safe, efficient, and productive industrial systems. Whether you choose piping or process, you’ll be contributing to the backbone of engineering operations.

At Petromech Baroda LLP, we offer certified and practical training courses in both piping design and process design. Our programs include hands-on software training, real project exposure, and placement support to help you start your career with confidence.

👉 Explore your strengths, understand your passion, and choose the path that suits you best. Piping design vs process design — whichever you choose, make sure it aligns with your future vision.