What is static equipment in the process industry

Static equipment stays still, but it powers every process with strength and safety.

Static equipment in the process industry refers to machines or tools that do not move while working. They stay fixed in one place and help with important jobs like holding pressure, storing liquids or gases, or transferring heat. These are commonly used in industries such as oil and gas, chemical plants, power stations, pharmaceuticals, and manufacturing plant. Even though they don’t rotate or spin, they handle high pressure, temperature, and chemicals every day. Without static equipment, many industrial processes would come to a halt.

Table of Contents

Why is Static Equipment so Important?

Static equipment is like the foundation of a building—it doesn’t move, but everything depends on it. In process industries, it helps with:

- Storing raw materials and products

- Separating mixtures like oil, gas, and water

- Heating or cooling fluids

- Supporting chemical reactions

These tasks are critical for running a safe and efficient plant. Static equipment is also designed to last long and work under tough conditions.

What are Common Types of Static Equipment?

Here are some of the most used static equipment in industries:

1- Pressure Vessels

Pressure vessels, a key type of static equipment in the process industry, are strong containers used to store gases or liquids safely under high pressure. They are carefully designed to handle internal stress and prevent leaks or bursts during operation. These vessels are typically made from durable materials like carbon steel or stainless steel and undergo rigorous testing to ensure safety. Built according to international standards such as ASME (American Society of Mechanical Engineers), pressure vessels play a vital role in maintaining safe and efficient industrial processes.

Common uses include:

- Storing and transporting chemicals or gases at high pressure

- Separating oil, gas, and water in refineries and chemical plants

2- Heat Exchangers

Heat exchangers are devices that transfer heat between two fluids without letting them mix. One fluid gets heated while the other gets cooled. They are made of metal tubes or plates that allow heat to pass through easily. Heat exchangers are commonly used in boilers, power plants, and chemical industries to control temperature and improve efficiency.

Common uses include:

- Heating or cooling process fluids

- Saving energy by reusing heat from other operations

3- Storage Tanks

These tanks are used to store liquids at normal or low pressure. They are available in different shapes and sizes based on the type of liquid they hold. Storage tanks are usually made of materials like carbon steel, stainless steel, or fiberglass to prevent corrosion and leakage. They play an important role in maintaining a steady flow of materials in the process industry.

Common uses include:

- Storing water, oil, or chemicals

- Acting as buffer tanks to control and balance process flow

4- Columns and Towers

These are tall vertical vessels used to separate different parts of a mixture. Inside them, there are trays or packing that help in the separation process. They are mostly used in oil refineries and chemical plants to clean or refine products.

Common uses include:

- Refining crude oil into useful products

- Removing unwanted gases from process streams

5- Reactors

Reactors are vessels where chemical reactions happen. They are designed to control temperature and pressure during the reaction.

Common uses include:

- Making fertilizers, plastics, medicines

6- Filters

Filters are devices used to remove solid particles or contaminants from liquids or gases. They are fixed in pipelines or vessels and work without any moving parts.

Common uses include:

- Purifying process fluids

- Protecting downstream equipment

- Ensuring product quality

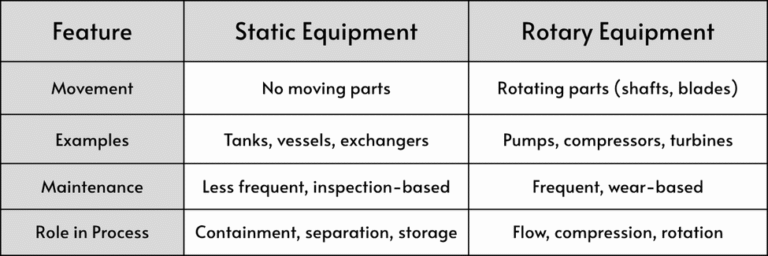

How is Static Equipment Different from Rotary Equipment?

Static equipment has no moving parts and includes vessels, tanks, heat exchangers, and columns used for storing, separating, or transferring heat.

Rotary equipment, like pumps, compressors, and turbines, has rotating parts such as shafts or blades and helps move fluids or generate power.

Both types are essential in process plants—static equipment supports operations, while rotary equipment drives movement and energy flow.

How to Design of Static Equipments

Designing static equipment in process industry is a careful and technical task. Engineers must consider many factors to ensure the equipment works safely and lasts long—even under extreme conditions.

Pressure and Temperature

Every piece of static equipment must be designed to handle the maximum pressure and temperature it will face during operation. For example, a pressure vessel in a refinery may need to withstand 100+ bar pressure and temperatures above 300°C. If the design is weak, it can lead to leaks or even dangerous failures.

Material of Construction

The choice of material depends on what the equipment will hold. For corrosive chemicals, engineers may use stainless steel, nickel alloys, or lined carbon steel. For water or non-reactive fluids, mild steel might be enough. The goal is to choose a material that is strong, safe, and cost-effective.

Safety Codes and Standards

Static equipment must follow international and national codes like:

- ASME Section VIII for pressure vessels

- API 650/620 for storage tanks

- IS 2825 for Indian standards

- TEMA for heat exchangers

These codes provide rules for thickness, welding, testing, and inspection. Following them ensures the equipment is safe, certified, and ready for industrial use.

Corrosion Resistance and Lifespan

Since static equipment often handles chemicals or stays outdoors, it must resist corrosion, rust, and wear. Engineers add coatings, linings, or cathodic protection to extend life. A well-designed vessel or tank can last 15–25 years with proper maintenance.

Engineering Software and Tools

Modern design uses software like:

- PV Elite for pressure vessels

- AutoCAD/Inventor for 3D modeling

- ANSYS for stress analysis

- ETAP or CAESAR II for piping and load checks

These tools help engineers simulate real conditions and optimize the design before manufacturing.

Want to Become an Expert in Static Equipment Design?

If you’re a student, fresher, or working engineer, you can master these design principles by joining our course:

👉 Static Equipment Design Course

This course covers everything from basic theory to real-world applications, including design codes, and case studies. By the end, you’ll be confident in designing pressure vessels, tanks, exchangers, and more—ready for interviews or industry projects.

Who Should Learn About Static Equipment?

This topic is useful for:

- Diploma or degree in mechanical engineering

- Freshers preparing for interviews

- Plant operators and technicians

- Project engineers and consultants

Understanding static equipment helps you work better in industries and design safer systems.

Final Words on Static Equipment in the Process Industry

Static equipment in the process industry may not have moving parts, but it plays a powerful role in keeping operations safe, stable, and efficient. From storing chemicals to separating mixtures and transferring heat, these components are the silent workhorses of every plant.

Understanding how static equipment is designed, maintained, and used gives engineers a strong foundation for working in oil & gas, chemical, and power sectors. Whether you’re a student or a professional, mastering this topic opens doors to better projects, smarter decisions, and a safer workplace.