The Importance of Design in Engineering for Industry Success

Design in engineering is not just about making drawings—it is the backbone of every successful project. From oil & gas to power, chemical, infrastructure, and manufacturing industries, design determines whether a system will run safely, efficiently, and cost-effectively for years.

When engineers design equipment or systems, they are not only creating layouts but also performing calculations, sizing materials, and ensuring compliance with international standards. A well-executed design helps avoid costly breakdowns, accidents, and inefficiencies.

In this blog, we will explore why design in engineering is important and discuss the scope of design across major disciplines like piping, static equipment, rotary equipment, process, electrical, instrumentation, civil, HVAC, and panel design.

Table of Contents

Importance of Design in Engineering

Design is the first and most critical step in engineering. Without a proper design, no construction, installation, or manufacturing can move forward. Some key reasons why design is important in engineering include:

Safety: Proper design ensures that equipment can withstand pressure, temperature, and environmental conditions.

Efficiency: Well-designed systems save energy, reduce wastage, and improve productivity.

Cost-effectiveness: Optimized design lowers material cost, reduces downtime, and improves return on investment.

Compliance: Design must meet international codes and standards like ASME, API, IEC, IS, NEC, and TEMA.

Sustainability: Good design reduces environmental impact and supports long-term reliability.

Let’s now explore how different engineering disciplines contribute through design.

Piping Design in Engineering

Piping Design is one of the most demanding fields in mechanical engineering. It is essential in both greenfield (new projects) and brownfield (existing plant modifications).

Key responsibilities in piping design include:

Sizing and selecting fittings such as elbows, tees, reducers, valves, flanges, gaskets, and end caps.

Pipe thickness calculation based on material, pressure, and temperature.

Layout planning of piping systems within plant space.

Stress analysis to ensure pipes can handle loads, vibrations, and thermal expansion.

Piping engineers play a major role in oil & gas, petrochemicals, refineries, and power plants.

Static Equipment Design in Engineering

Static Equipment Design deals with equipment that does not have moving parts but is vital for plant operation.

Examples of static equipment include:

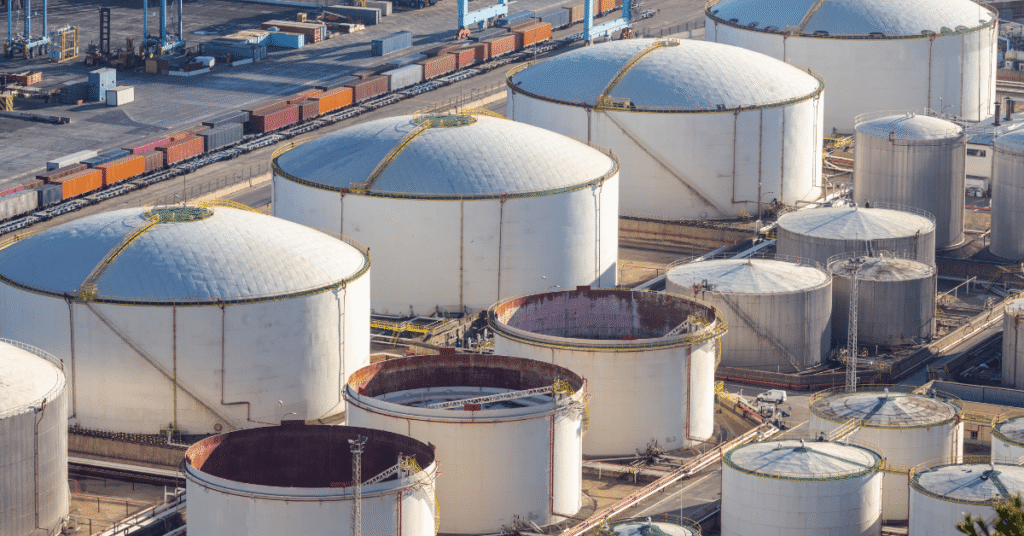

Pressure Vessels – used to store gases and liquids at pressure.

Heat Exchangers – transfer heat between two fluids.

Storage Tanks – store raw materials and products.

Columns and Reactors – used in chemical and petrochemical industries.

Design is done as per international codes such as ASME, API, and TEMA, ensuring durability and mechanical integrity. Static equipment engineers also perform thickness calculations, material selection, and mechanical design checks.

Rotary Equipment Design in Engineering

Rotary equipment design focuses on machines with moving parts. These are the heart of industrial plants since they keep systems running continuously.

Rotary equipment includes:

Pumps

Compressors

Turbines

Blowers and Agitators

Designing rotary machines requires performance calculations, material selection, lubrication analysis, and vibration studies. Engineers also check alignment, balancing, and efficiency to ensure long life and low maintenance.

Electrical Design in Engineering

Electrical Design is essential for any industry as it ensures uninterrupted power supply and safe operation of systems.

Electrical engineers design systems such as:

DG sets, transformers, motors, UPS, and batteries.

Switchgear, bus ducts, power reactors, CTs, PTs, and cables.

Plant earthing, lightning protection, and illumination systems.

They work according to IEC, IS, and NEC standards. Electrical design not only supports industrial plants but also residential, commercial, and infrastructure projects.

Process Design in Engineering

Process Design Engineering is the brain of plant operation. Process engineers ensure that the plant operates safely, efficiently, and economically.

Key responsibilities include:

Designing PFDs (Process Flow Diagrams) and P&IDs (Piping and Instrumentation Diagrams).

Sizing equipment such as heat exchangers, vessels, control valves, columns, and reactors.

Running simulation models to optimize energy consumption and production.

Designing safety systems like PSVs (Pressure Safety Valves).

Process design engineers directly influence the productivity and profitability of plants.

Instrumentation Design in Engineering

Instrumentation Design ensures accurate measurement and process control in plants.

It covers:

Control valves and safety valves.

Measurement instruments for flow, temperature, pressure, and level.

Advanced analyzers and automation systems.

Instrumentation engineers help plants achieve automation, efficiency, and safety. With growing digitalization, this field is becoming more important every day.

Civil and Structural Design in Engineering

Civil and Structural Design provides the foundation and physical support for all industrial plants and infrastructure projects.

It includes:

Beams, columns, slabs, and footings.

Equipment supports, staircases, ladders, and platforms.

Earthquake and wind load analysis for safety.

Civil engineers ensure compliance with building codes and guarantee structural stability against natural forces.

HVAC Design in Engineering

HVAC design plays a key role in comfort, safety, and utility systems of industries, commercial buildings, and cleanrooms.

It includes:

Heating, ventilation, and air conditioning systems.

Air distribution, duct sizing, and load calculations.

Specialized cleanroom design for pharmaceuticals and electronics industries.

A well-designed HVAC system improves air quality, worker comfort, and energy savings.

Panel Design in Engineering

Electrical panels are like the nervous system of plants and buildings.

Panel Design covers:

MCC (Motor Control Center) and PCC (Power Control Center).

Distribution boards, control panels, and automation cabinets.

Although mainly done by electrical engineers, with proper training, professionals from other fields can also work in panel design.

Where to Learn Design in Engineering

To explore all these disciplines in detail, engineers must receive practical training. Petromech Baroda LLP is one of the leading institutes in India providing industry-oriented design courses across piping, process, electrical, instrumentation, civil, static equipment, rotary equipment, and HVAC.

The institute focuses on real-world applications, preparing engineers for EPC (Engineering Procurement & Construction), MEP (Mechanical, Electrical & Plumbing), and pharmaceutical industries. Along with Petromech, many other reputed institutions also offer specialized training programs.

Why Design in Engineering is the Backbone of Industry

Design in engineering is not limited to calculations or drawings. It is about creating workable, safe, and efficient solutions that run industries, power cities, and improve human life.

A strong foundation in design helps engineers shape not only plants and infrastructure but also the future of technology and sustainability.

This is why design is the ultimate backbone of engineering—without it, no project can stand strong.